By David Stuart

A comprehensive study of non-halogenated fire retardants conducted by RISE Research Institutes of Sweden was recently published in the Journal of Applied Polymer Science. The authors took a deep dive into the state-of-the-art fire-retardant systems that may be able to replace the traditional brominated fire retardants relied on today. The acrylonitrile-butadiene-styrene material studied in the article is utilized by the transportation, electronics, appliance, and other household industries to provide hardness, strength, and rigidity for many different components in their systems. Many of these applications need a level of fire-retardancy. The best performing halogen-free systems were compared to one another in a stringent systematic evaluation. The key characteristics evaluated were toxicity, fire performance and thermal decomposition, and mechanical properties. Of the 25 systems tested, only a few systems were found to be adequate in all the categories. The best performing fire-retardant package was shown to be the formulation with the AlPi/APP/GrafGuard 280-50N (5%).

The toxicity evaluation was based upon several sources, including the ECHA candidate list of very high concern, the Substitute-it-now list from ChemSec, and the CLP database, which uses the Green Screen Assessment and Pharos tool. These resources detail human health risks as well current environmental impacts of the base chemicals and the substituents. Expandable graphite was not included in any of the consulted lists of substances.

The fire performance and thermal decomposition characteristics were evaluated using the horizontal burning tests of UN/ECE Regulation 118, Annex 6. The vertical burning tests were based on the UL94 test standard. The cone calorimetry testing was done according to ISO 5660-1 with a heat flux of 50kW.m-2. The thermogravimetric testing was performed on a TGA/DSC 1 Stare System by Mettler Toledo.

Many sample formulations performed poorly on the horizontal flame test and were removed from consideration and further testing. The remaining samples were compared using the UL94 testing method. Only two experimental samples achieved the UL94V0 rating, and the best performing material for burn length was the sample containing GG 280-50N. The cone calorimetry tests also showed outstanding results for the formulation with the GG 280-50N, while the smoke produced was one of the lowest measured.

The mechanical properties were evaluated through Charpy impact testing according to ISO 179 using a CEAST 9050 instrument. The mechanical strength of the systems was studied for modulus and stress at break. Of the best performing materials in the fire testing, the sample containing the GG 280-50N tested highest for modulus and middle of the pack for the stress at break.

When all the testing is compared, the best performing fire-retardant package was shown to be the formulation with the AlPi/APP/GG 280-50N (5%). For this formulation, the horizontal burn test was passed, the UL94 V0 rating was achieved, and the cone calorimetry THR and PHR were among the lowest with minimal smoke generation. The reduction of mechanical properties was apparent but acceptable.

The article was authored by Angelika Bachinger, Anna Sandinge, Karin M Lundquist, Anna Strid, and Guan Gong from RISE Research Institutes of Sweden. It was recently published in the Journal of Applied Polymer Science. Please read the entire article at the link below:

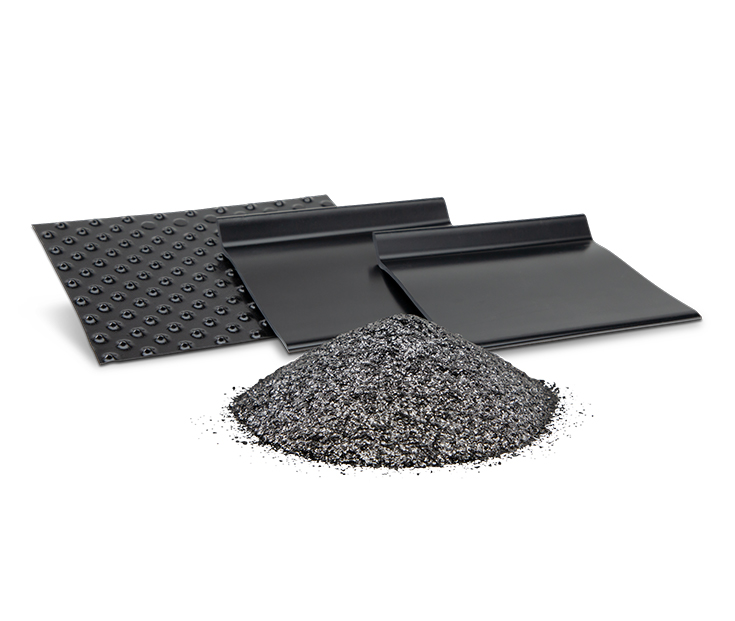

GrafGuard® expandable graphite flake is a non-halogenated fire retardant additive for materials that require improved fire-protection characteristics.