Product and industry innovations factor significantly in NeoGraf Solutions’ history. In the 1980s, we not only created a graphite fluid sealing solution to replace asbestos, but also built a market around it. In the 1990s, NeoGraf introduced the first graphite thermal interface material for use in DC-DC converters and the first graphite heat spreaders for plasma and LCD televisions and more. Here is a snapshot of the products NeoGraf offers today.

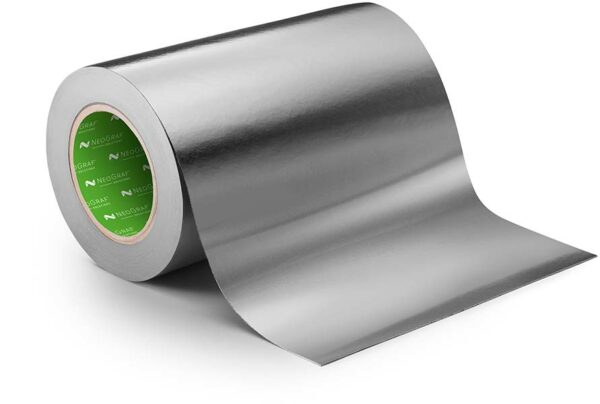

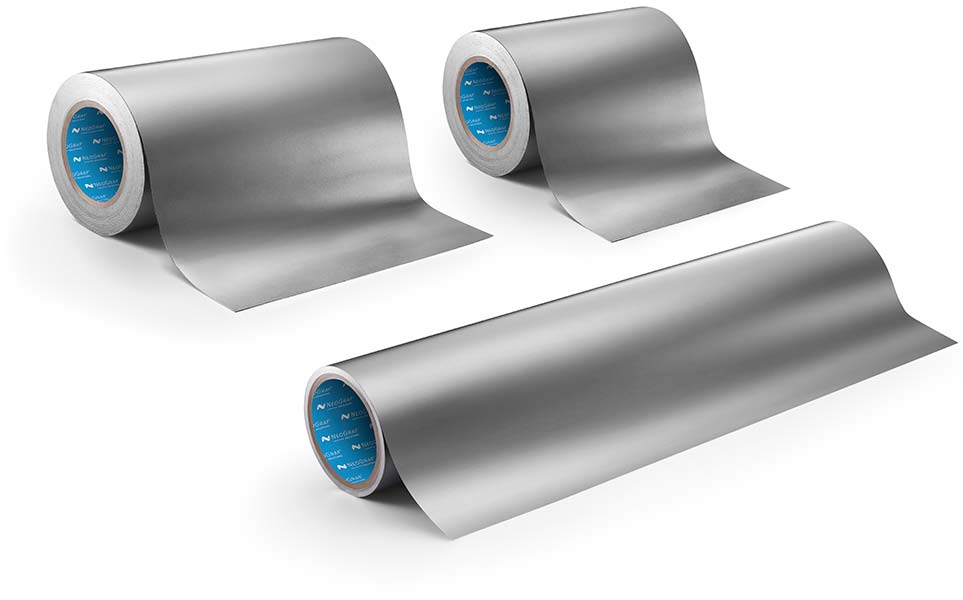

Thermal Management Solutions

NeoGraf Solutions’ eGraf® products offer a comprehensive range of thermal management solutions for electronics and battery applications. Furthermore, their innovative portfolio includes Heat Spreaders and Thermal Interface Materials, providing exceptional thermal properties and performance. Additionally, NeoGraf’s flexible graphite products are designed to meet diverse thermal management needs, thereby ensuring optimal performance across various applications.

Powders & Additives

Fire Stop Materials

GrafGuard® expandable graphite flake is a non-halogenated fire retardant additive designed to enhance fire-protection characteristics in various materials. Ideal for building materials and automotive applications, GrafGuard® helps meet stringent fire safety codes. Additionally, GrafGuard® improves the performance of other fire-retardant additives, including phosphates, magnesium hydroxide, and nitrogen compounds. Enhance your fire safety solutions with GrafGuard® expandable graphite flakes.

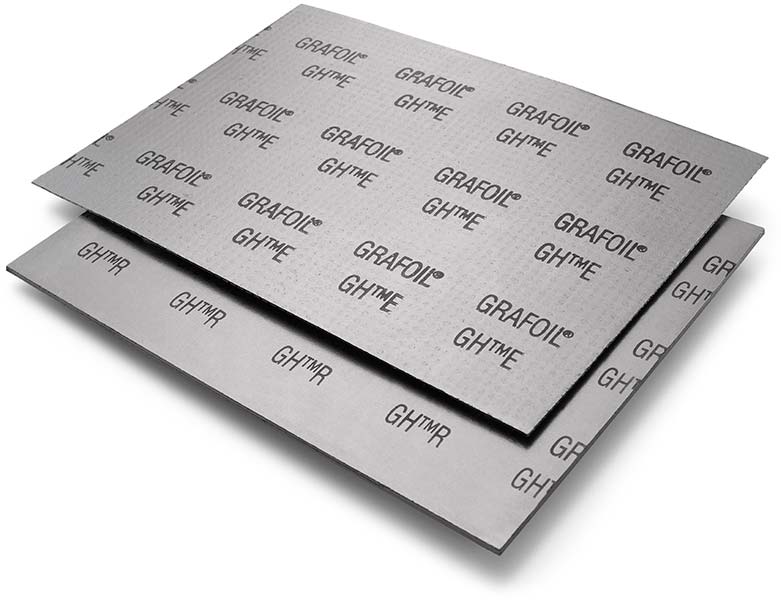

Gaskets & Sealants

Introduced in 1967, GraFoil® material revolutionized the flexible graphite industry as the original fluid sealing solution made from pure, natural graphite flake. Renowned for its exceptional resistance to heat, fire, corrosion, and aggressive chemicals, GraFoil® stands out as the most versatile and universally applicable sealing solution on the market and is successfully used in a wide range of applications across diverse industries.

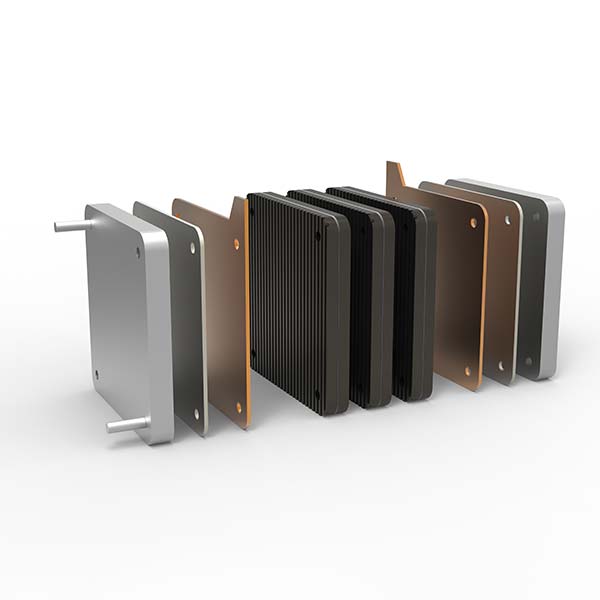

Fuel Cells

Since the 1990s, NeoGraf has been at the forefront of designing flexible graphite for Proton Exchange Membrane Fuel Cells. Our GrafCell materials portfolio embodies over 20 years of optimized bill of material and processing parameters, ensuring the most reliable flexible graphite for Flow Field Plates. GrafCell materials excel in high power density applications, including mass transportation, fleet service vehicles, and material handling equipment. Enhance your fuel cell technology with NeoGraf’s proven expertise in flexible graphite solutions.