Solutions That Help Shape Our World

NeoGraf is the world leader in graphite material science – and we have been for over a century. It’s why engineers and material scientists around the world continue to rely on NeoGraf – we’re the key ingredient that makes the future possible. It’s our people, our dedication to innovation and our unstoppable curiosity that makes the difference.

Why follow when you can lead? At NeoGraf Solutions, that has been our mission since our inception more than 140 years ago. Our people are passionate problem solvers. We’re curious. Innovative. And every day we strive to provide the most comprehensive graphite solutions in the world. Not one to rest on our laurels, we solve problems our customers didn’t even know they had. And NeoGraf will continue to evolve with global market trends to provide graphite solutions for not only today’s products, but tomorrow’s, as well.

What Our Customers Are Saying …

“Orders are always on time, never any issues with supply.”

“Dave Stuart (NeoGraf Research Scientist) has great expertise, and is always willing to help with technical problems, literature requests, or analytical tests. He is very responsive despite the different time zones and we appreciate his effort in coming to visit our sites regularly.”

“I was impressed with NeoGraf from a technical perspective and their speed of response.”

“NeoGraf was proactive in making improvements we didn’t even ask for.”

“NeoGraf showed us other applications in battery to enhance thermal (cell-to-cell) barrier performance which we had not considered.”

Ideas That Matter

Our customers rely on NeoGraf to take their products from inception, through development and across the finish line. Whether it’s making a smartphone even lighter than ever imagined or ensuring utility poles will resist wild fires, NeoGraf is writing the playbook for the future of innovation and thermal management solutions.

Driving Industry Growth

The graphite industry is growing at lightning speed. And NeoGraf is innovating even faster. NeoGraf products are in your pocket, your briefcase, your neighborhood, your home. Some of the largest companies in the world trust NeoGraf to deliver technology at levels never seen before.

by 2024

Graphite industry market growth

of new cars

on the road will be electric by 2025

increase

in US investment in Lithium ion battery technology in 2020

number of new mega-factories worldwide in 2020

need for graphite

for Lithium batteries growth rate by 2024

Markets

Telecommunications / Computing

As our devices get smaller, our networks get faster, and our world becomes more interconnected, demand for the highest performing thermal interface materials is not only needed; it’s required. Flexible graphite, developed by NeoGraf, provides a material that is easy to install, has an unlimited lifetime, and is able to handle a wide variety of surfaces.

Markets

Consumer Electronics

It’s a fact – computers are getting lighter. Cell phones are getting smaller. And televisions are getting thinner. How? One word: graphite. Lightweight, thin and flexible graphite is enabling today’s most desired consumer electronics technology… and NeoGraf is leading the way. NeoGraf’s development team works hand-in-hand with engineers at the world’s technology leaders to make the most advanced electronics possible.

Markets

Manufacturing

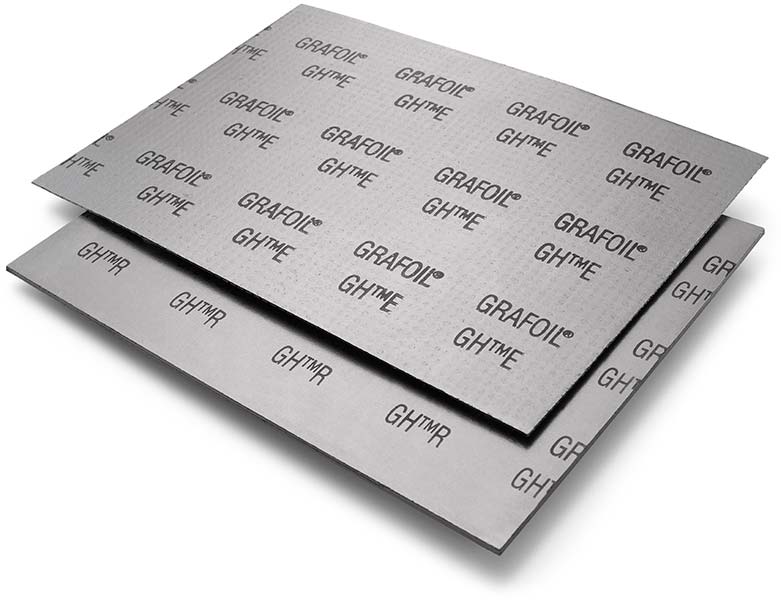

NeoGraf is the recognized leader in the industry and manufactures more than 50 types of graphite laminates to meet virtually every industrial sealing application in the manufacturing industry. From inserts in Teflon® carbon steel and stainless steel to tanged metal and plastic… we can do it all in sizes ranging in thickness from .015 inches to .254 inches and widths up to 24 inches.

Markets

High Performance Materials

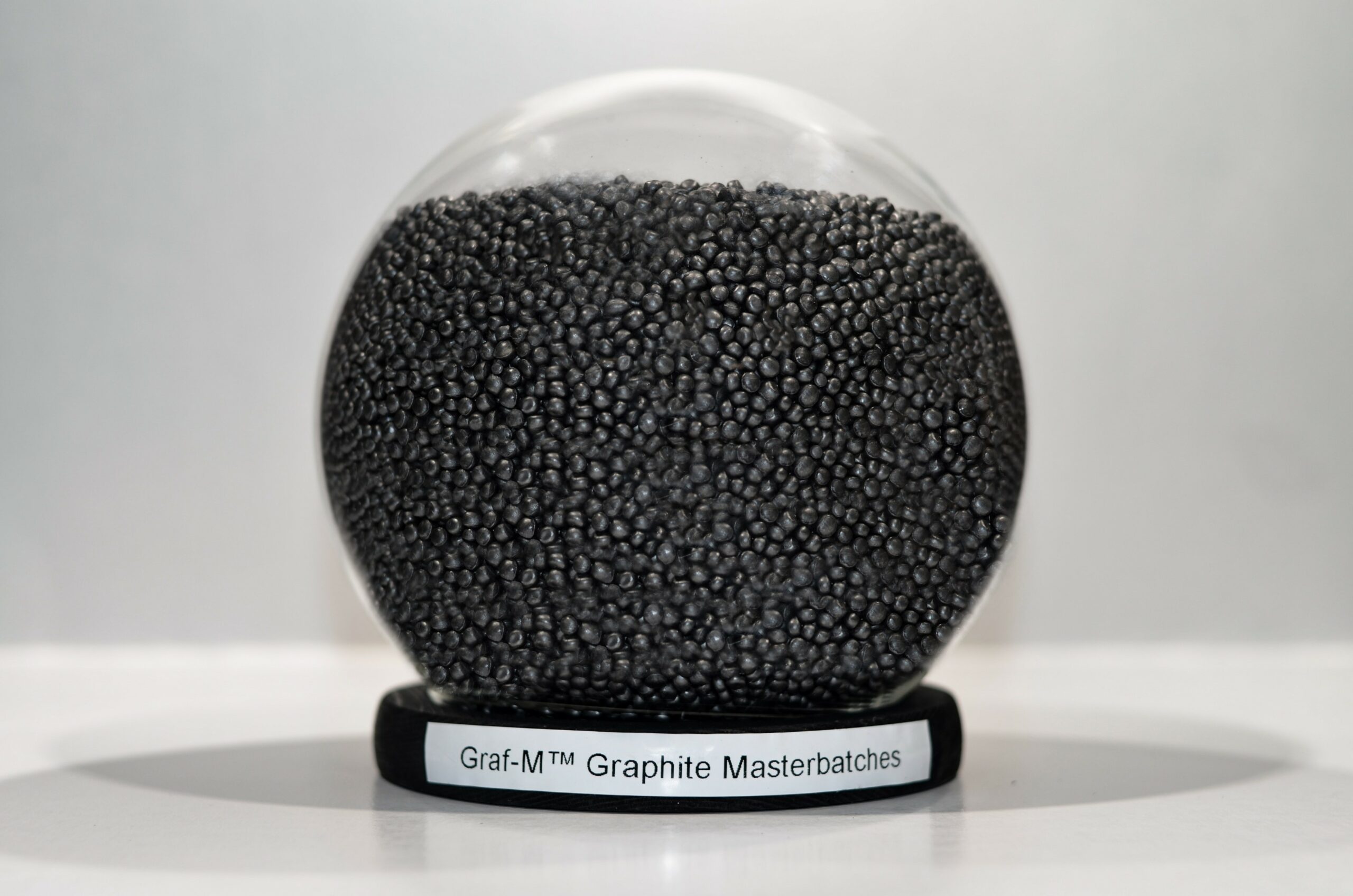

Graphene is a material that is gaining prominence for its unique properties. At NeoGraf, we have a portfolio of high-performance graphite and graphene nanoplatelet products targeted towards a variety of specialty applications. NeoGraf’s graphite and graphene-based products excel when put to the test of extreme temperatures and high-performance applications.

Markets

Building & Construction

Graphite’s endless possibilities never cease to amaze, even the most technically advanced minds in building and construction. Our treated graphite can be inert for years, but when exposed to the heat of a fire, it instantly expands to several hundred times its original volume, providing both a fire-stop and a smoke-suppressing char layer. NeoGraf has created a portfolio of graphite additives, some with fire retardant properties and some with electrical/thermal characteristics for use in putties, coatings, foams, roofing materials, and concrete.

Markets

Energy

Sustainability is an essential concept in any industry, but it’s especially important in energy storage. These situations often require the need to store energy for long periods of time, but also be compact and reliable. Economical, flexible natural graphite from NeoGraf is the perfect solution, as it can be used as an aluminum replacement for many long-life battery systems. In addition, NeoGraf’s GrafCell® Materials are used throughout the world in flow Field Plates for Proton Exchange Membrane fuel cells.

Markets

Transportation

Graphite is leading the transportation revolution. From heat spreaders in batteries, to thermal interface material in LED headlights, to engine gaskets and seals, to fire retardant composites and foams, graphite is changing how we interact with transportation on a daily basis. And NeoGraf is the power behind it, developing new ways to use graphite that every transportation enthusiast would admire.

Science

Thermal Management in Batteries Used in the UAV and eVTOL Industries

The UAV and eVTOL industries have experienced significant growth over the past decade, driven by advancements in technology and increasing applications across various sectors, including military, agriculture, logistics, surveillance, and entertainment. These advancements have led to improved performance and safety of UAVs and eVTOLs, including the critical battery systems that power these aerial vehicles. The engineers and the R&D team at NeoGraf Solutions, continue to find the best graphite thermal management solutions for this rapidly evolving market. Learn More

History & Innovations

Powering the Impossible Since 1881

NeoGraf has been the world leader in the industry for more than 140 years, in fact, they’ve been developing the most comprehensive graphite solutions since 1881. Our products are the reason why some of today’s most technologically-advanced products are able to perform and work the way they do. Our depth of knowledge, training, understanding and discipline is unmatched in the market, and there’s no stopping where we can go from here.