Graphene is a material that is gaining prominence for its unique properties. At NeoGraf, we have a portfolio of high-performance graphite and graphene nanoplatelet products targeted towards a variety of specialty applications. NeoGraf’s graphite and graphene-based products excel when put to the test of extreme temperatures and high-performance applications.

Intumescent Fire Retardant Additives

GrafGuard® graphite flake materials have engineered intumescent temperatures tailored to meet challenging processing requirements, from room temperatures to 280°C. Their product consistency and unlimited shelf life are unsurpassed. Used in many construction materials regulated by fire-safety codes to limit fire propagation, GrafGuard® fire-stop graphite flake material is non-halogenated, lead- and chrome-free, used synergistically with other commonly used flame retardants in putties, pastes, coatings, foams, and roofing materials.

NeoGraf products:

Thermally and Electrically Conductive Additives

Graf+® graphite powders can be added to a range of polymers to enhance thermal and electrical conductivity, reduce degradation to UV radiation, and increase insulation value in foams and boards. NeoGraf’s Graf+ natural and synthetic graphite powders are available in a range of particle sizes, BET surface areas, Scott densities, and purities depending on the end use application.

NeoGraf products:

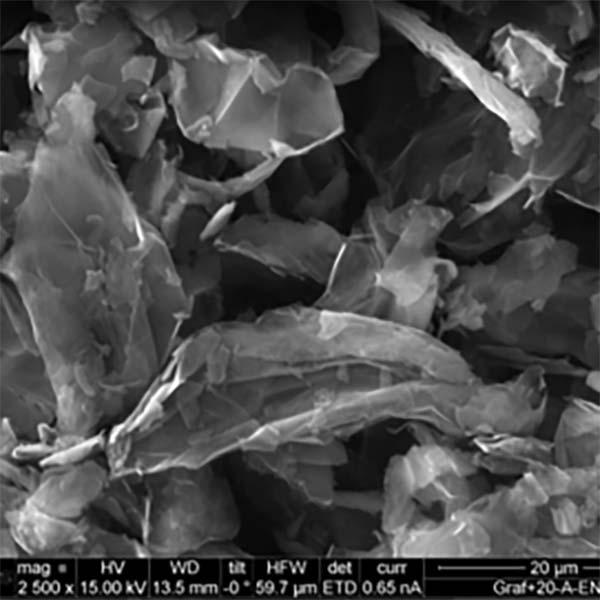

Graphene Nanoplatelets

Graphene is a single layer of graphitic carbon, whereas, graphite is a bulk material comprising >~ 10 layers. High quality graphene is very strong, nearly transparent, an excellent conductor of heat and electricity, and has excellent barrier properties. As part of our Graf+® product portfolio, NeoGraf offers graphene nanoplatelets (GNP’s) in a range of particle sizes and BET surface areas depending on the end use application.