It’s a fact – computers are getting lighter. Cell phones are getting smaller. And televisions are getting thinner. How? One word: graphite. Lightweight, thin and flexible graphite is enabling today’s most desired consumer electronics technology… and NeoGraf is leading the way. NeoGraf’s development team works hand-in-hand with engineers at the world’s technology leaders to make the most advanced electronics possible.

Smartphones

Today’s smartphones have unique thermal challenges. They contain a hot processor that must be cooled, the shell of the phone has strict touch temperature limitations, and the display must be protected from hot spots and thermal gradients. Plus, all of this must be done in a thin form factor. With the broadest range of ultra-high performance synthetic and natural graphite heat spreaders, NeoGraf Solutions has the right thermal solutions that will meet the performance needs of the industry.

NeoGraf products:

Tablets and Ultrabooks

As tablets and notebook computers become thinner and lighter, the need for high-performance heat spreaders has never been greater. Hot processors need to be cooled, while hot-spots on the shell must be eliminated. NeoGraf Solutions has a full range of graphite heat spreaders to match every device, from thin, high-performance synthetic to economical natural graphite. We have the ideal heat spreader to meet your needs.

NeoGraf products:

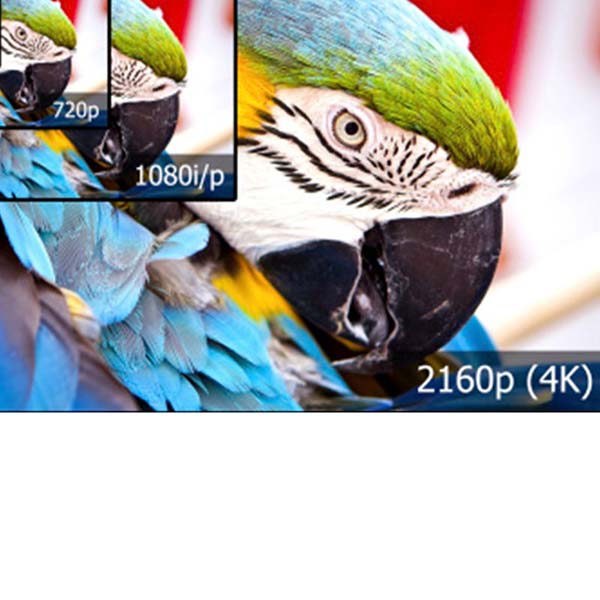

4K/8K Ultra HD TV

Thermal issues can cause severe problems for high-definition displays. For LCD/LED displays, uneven heating is a primary cause of Mura, the cloudy ghost images seen everywhere on the display, but especially prevalent in the corners. For OLED displays, non-uniform heating can cause uneven aging of the display, resulting in noticeable color distortions. High-performance natural and synthetic flexible graphite heat spreaders prevent these display problems, resulting in the highest quality picture available.

NeoGraf products:

Set-Top Boxes and Enclosed Electronics

Set-top-boxes and enclosed electronics have unique challenges. Hot components located inside a sealed plastic enclosure must be cooled without a resulting surface hot spot. Without fans or vents, heat must be removed from the interior and shed to the ambient environment. Cost-effective natural graphite is used to cool the hot components and to spread the heat evenly on the device shell, all without a resulting hot spot.