High Performance Non-Halogenated Graphite Fire Retardant Additive

GrafGuard® expandable graphite flake is a non-halogenated fire retardant additive for materials that require improved fire-protection characteristics. It can be found in building materials and automotive applications to meet increasingly stringent fire safety codes. GrafGuard materials also improve the performance of fire-retardant additives such as phosphates, magnesium hydroxide and nitrogen compounds.

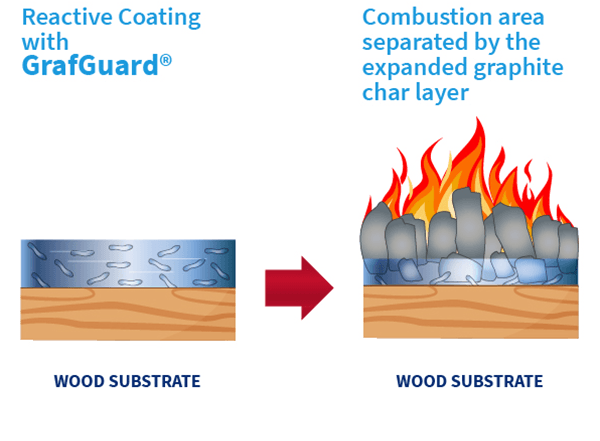

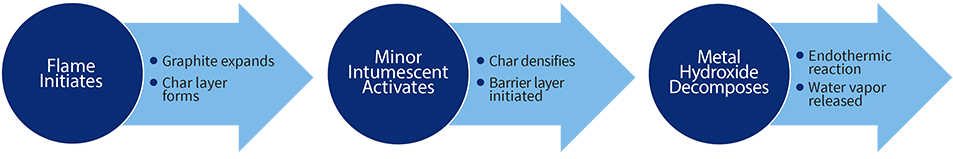

Upon exposure to high temperatures, the GrafGuard material expands and forms a graphite char layer that is more resistant to degradation than the carbon chars formed from typical chemical intumescent materials. GrafGuard material is manufactured without the lead or chromium that can be found in some other expandable graphite solutions.

GrafGuard flake has been shown to expand up to eight times more than competitive products, exhibiting superior performance even at low temperatures. This high expansion makes it possible to reduce loading levels and improve performance.

GrafGuard expandable graphite is suitable for use in many markets and applications, including:

- Building and Construction – GrafGuard materials reduce the need for harmful chemicals and help to improve fire protection characteristics of wood, foam, plastics, roofing, and other building and construction materials.

- Transportation – GrafGuard materials are used as a critical fire stop application in foams, insulation, cushioned seats, wall and ceiling panels, and carpet backing.

- Bedding – GrafGuard materials are used in natural and synthetic foams, pillows, mattress covers, and more in the bedding industry, acting as a fire retardant and adding a cooling effect to mattress and pillow products.

Why GrafGuard® Expandable Graphite Flakes?

Consumers and legislators alike continue to demand that manufacturers produce products that reduce human and environmental exposure to greenhouse gases, heavy metals, and other toxic substances. This is driving a variety of industries to search for high performing, cost-effective, nontoxic fire-retardant additives and solutions. The versatility, consistency, superior expansion performance, and high quality of GrafGuard expandable graphite as the only non-halogenated expandable graphite material sourced in North America make it a premier solution for a variety of applications.

GrafGuard® Expandable Graphite Flakes Product Portfolio

GrafGuard materials are offered in a range of onset temperatures, a range of expansion rates and a variety of particle sizes to meet your unique application requirements.

- Customized onset temperature from 160°C to 280°C

- Custom grade nomenclature (onset temperature, flake size, pH)

- Expansion volume range from 80 to 260 cm3/g

- Typical average particle size from 90 to 350 microns

- Controlled surface pH (from 4-9) makes GrafGuard materials compatible with any catalyst system

Features & Benefits

- Will not burn at any temperature

- Forms an effective insulating “char” layer that protects the substrate from heat and oxygen

- Expands up to eight times more than competitive products

- Exhibits superior performance at low temperatures

- Contains no halogenated fire-retardant additives

- Manufactured without the lead or chromium that can be found in other expanding graphite flakes

- Enables ideal application as an intumescent additive

- High volume manufacturing capability

- Only North American manufacturer of expandable graphite

- Reliable performance

- Consistent engineered activation temperatures to meet compounding/processing requirements

- Performance does not degrade with time or environmental exposure

- Meets many flame-stop performance targets at low loading levels

- Reduces smoke evolution

- Non-toxic, non-halogenated fire-stop additive

- World-leading expandable graphite application expertise

- Expandable graphite will not burn at any temperature

NeoGraf’s global team of application engineers specialize in developing and manufacturing high-quality flexible natural and synthetic graphite material solutions for today’s advanced applications. Regardless of your product design phase (concept, prototyping, or mass production), we offer technical answers and thermal modeling support to some of your most challenging problems with a fast response time

Media

GrafGuard® Expandable Graphite Systems Help Meet ASTM E-84 Testing Requirements

ASTM E-84 is the standard test method for assessing the surface burning characteristics of building products. A new white paper from NeoGraf Solutions, “GrafGuard® Expandable Graphite Systems Help Meet ASTM E-84 Testing Requirements” discusses how GrafGuard® expandable graphite expands into a charred intumescent foam when exposed to the heat or flame, protecting the substrate and helping to pass the ASTM E-84 requirements. Minimizing both the smoke development and flame spread maximizes the potential flame spread index classification of the material. [...]Learn More

GrafGuard® Expandable Graphite: A Safer Choice for Fire Protection

Protecting people and property from fire is crucial, and fire retardants play a vital role in achieving this goal. While various fire retardants exist, melamine-based options raise concerns due to their EU classification as substances of very high concern (SVHC) in the REACH regulations. GrafGuard® expandable graphite from NeoGraf Solutions is a safe and effective replacement for melamine-based fire retardants […..]Learn More

Changing the Reactive Coatings Market with Graphite

The reactive coatings market has become an integral part of society. Chemists, engineers, and product designers have taken notice as consumers expect superior product performance and appreciate value-added features to ensure their safety. Fire-retardant [...]Learn More

GrafGuard®: The Non-Toxic, High Performing Alternative for Fire Stop Applications

Overview Growing concern over environmental sustainability continues to drive the introduction of stringent regulations that affect nearly every industry and product. Reducing adverse environmental and health effects is of particular interest when examining manufacturing [...]Learn More

Systematic Evaluation of Bromine-free Flame-retardant Systems in Acrylonitrile-butadiene-styrene

By David Stuart A comprehensive study of non-halogenated fire retardants conducted by RISE Research Institutes of Sweden was recently published in the Journal of Applied Polymer Science. The authors took a deep dive into [...]Learn More

Patents

GrafGuard® expandable graphite flake products, materials, and processes are covered by one or more of the following US patents: 6,669,919. Other US and foreign patents granted or pending.

Markets

Safety Data Sheets

Sell Sheets

Technical Data Sheets

What Our Customers Are Saying …

“Orders are always on time, never any issues with supply.”

“Dave Stuart (NeoGraf Research Scientist) has great expertise, and is always willing to help with technical problems, literature requests, or analytical tests. He is very responsive despite the different time zones and we appreciate his effort in coming to visit our sites regularly.”

“I was impressed with NeoGraf from a technical perspective and their speed of response.”

“NeoGraf was proactive in making improvements we didn’t even ask for.”

“NeoGraf showed us other applications in battery to enhance thermal (cell-to-cell) barrier performance which we had not considered.”