NeoGraf has been the world leader in the industry for more than 140 years, developing the most comprehensive graphite solutions since 1881. Our products are the reason why some of today’s most technologically-advanced products are able to perform and work the way they do. Our depth of knowledge, training, understanding and discipline is unmatched in the market, and there’s no stopping where we can go from here.

NeoGraf History

Transforming Markets Since 1881

NeoGraf’s story began in 1881 as an independent Cleveland carbon company start-up, the Boulton Carbon Company, supporting the electric arc-lighting boom of the early 1880s. Due to the efforts of Cleveland businessman Washington H. Lawrence, we were transformed into the world’s largest carbon business, the National Carbon Company. In 1917, we became part of the historic effort to integrate the new oxyacetylene industry as a founding member of the massive Union Carbide and Carbon Corporation. From the 1920s to the 1990s we remained part of Union Carbide Inc. In 1995 we separated and became GrafTech International. Now, as NeoGraf Solutions, we are a stand-alone carbon and graphite company and a highly successful portfolio company of Edgewater Capital Partners. Our product innovations have created new markets for graphite-based materials over 140 years… and we aren’t finished innovating yet.

Innovations

Foldable Device Screens

In 2019, NeoNxGen™ Thermal Management Solutions were specified in the reference design for laptops with foldable screens. Our thick, high-performance flexible graphite surpassed performance expectations after cycle testing with endless opening and closing to simulate real-life activity.

Marine Batteries

Starting in 2012, SpreaderShield™ Heat Spreaders have been used in high-volume marine battery systems. Many countries in Europe have strict restrictions on carbon emissions from ships and ferry boats. Graphite enables batteries that meet all safety and environmental regulations yet are smaller and lighter.

International Space Station

In 2011, HiTherm™ Thermal Interface Material was used to solve a thermal issue on the International Space Station. HiTherm won’t ever outgas or wear out, making it perfect for even the most challenging long-term TIM applications.

LED Lighting

Since 2011, HiTherm™ Thermal Interface Material (TIM) has been used to cool millions of LED lights. Graphite is a stable, solid material. It will never dry out, leak, pump out, or wear out.

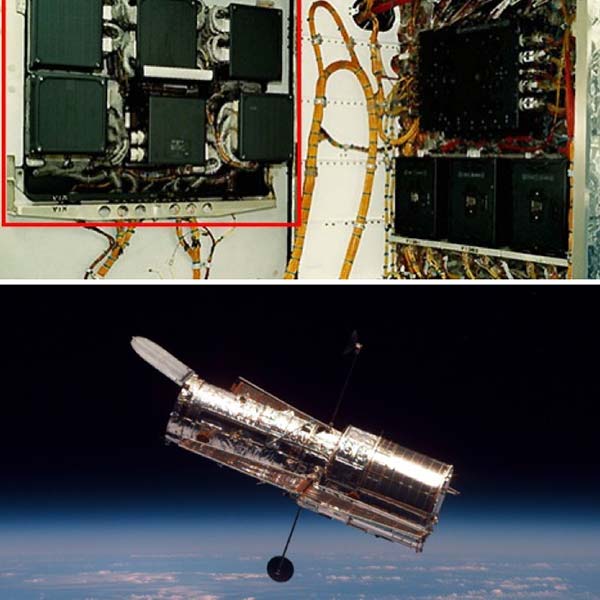

Hubble Space Telescope

In 2009, HiTherm™ Thermal Interface Material was used for thermal management on the retrofitted “Science Data Formatter” on the Hubble Space Telescope. The new assembly was installed during Servicing Mission 4 (SM4) and has successfully been in continuous use since then.

Mobile Phones

Since 2008, SpreaderShield™ Heat Spreaders have been used in approximately 300 million smartphones. Graphite cools the processor, reduces thermal gradients on the display, and lowers touch temperature on the shell. Today the typical smartphone uses 4 to 6 pieces of flexible graphite for thermal management.

Laptop/Tablet/Notebook Computers

Since 2005, SpreaderShield™ Heat Spreaders have been used for thermal management in approximately 150 million notebook computers and tablets. Graphite cools the processor and reduces shell touch temperatures while making computers thinner and lighter.

Large Screen TVs

Starting in 2003, SpreaderShield™ Heat Spreaders have been used to make millions of large screen TVs thinner and lighter while significantly improving thermal gradients and color consistency across the display. Before lightweight graphite was introduced for thermal management, plasma TVs of the early 2000s could weigh up to 80 pounds.